From structure and machinery import to commissioning and schooling, we assistance you at just about every stage with the journey. We now have assisted builders, builders, and architects convey their visions to life over time.

Horizontal AAC Block Machines :- Molds that go horizontally down the generation line really are a aspect of horizontal machines. These are routinely employed in higher-quantity manufacturing environments and supply flexibility in running distinct block sizes.

Correct processing enhances the regularity and top quality of the AAC blocks, cutting down content waste and bettering production effectiveness.

The reducing part options significant-precision cutting tools that slices the pre-cured blocks into preferred dimensions and designs with minimal wastage.

Autoclave :- The autoclave is often a superior-strain steam chamber that cures the Reduce blocks below controlled ailments. This process boosts the strength and toughness in the AAC blocks.

The packing area involves automatic units for stacking, packing, and securing completed AAC blocks for transportation.

Integrates a sturdy generation management method that enables serious-time monitoring and control of the manufacturing procedure. This system makes sure operational effectiveness, regularity in solution top quality, and the chance to adapt to different manufacturing needs.

Generally known as brick-making machines, our AAC Block Making Machines are manufactured with remarkable excellent requirements to be sure longevity and efficiency. Devoted to excellence, we provide these superior-efficiency machines at aggressive prices, making them an ideal choice for companies in the construction marketplace.

State-of-the-art checking systems ensure the very best high quality criteria are managed throughout the production course of action. Sturdy machinery with minimal maintenance desires decreases downtime and ensures ongoing Procedure. Factors Equipped by Brickwell

Brickwell delivers automated systems with the fabrication and circulation of steel mesh, which serves as reinforcement for AAC panels.

Our AAC division continues to be focused on supporting high quality development as a result of Superior and efficient manufacturing devices across India.

With more than 20 years of experience, we provide a single-quit support alternatives that optimize generation effectiveness and potential even though ensuring lengthy-time period trustworthiness.

Conveyor Devices: These devices transportation raw products and finished products and solutions throughout the creation line, making sure effectiveness and lowering handbook labor.

They manage each and every phase from the creation approach, from packaging to mixing. Huge manufacturing facilities that demand superior output while preserving regular top quality are an ideal fit for these devices.

Reducing Machine:-slicing machines slice it into individual blocks. These machines can conduct each vertical and horizontal cuts.

The pouring procedure is designed for exact and controlled filling of molds Along with the AAC slurry, while the pre-curing method makes sure the combination achieves The perfect regularity and energy prior to even further processing. This portion assures dimensional precision and improves the caliber of the ultimate product.

Moulds: Moulds condition the slurry into blocks. They may be customized to generate various dimensions and shapes of AAC blocks.

An AAC block making machine is usually a specialised piece of kit made to generate autoclaved aerated concrete blocks. These machines streamline the manufacturing course of action by automating many stages including mixing, pouring, cutting, and curing. The end result is really a large-high-quality item that meets the calls for of contemporary construction.

Vertical AAC Block Machines :- Vertical molds that vacation as a result of each individual creation step are utilized by vertical machines. They can be completely automated for top-capacity output and improve House performance.

Productive undertaking administration and preparing Dependable devices provide and logistics Supervised installation for precision and high quality With a strong study and development crew, Superior output programs, and a effectively-founded provide chain, Brickwell ensures thorough and timely answers for its buyers.

Giving you the most beneficial choice of mini aac block manufacturing plant, reduced financial investment startup aac plant, aac updragable alc block plant, modest aac blocks plant, absolutely automatic aac plant and semi automatic aac block making machine with helpful & well timed shipping.

We provide an extensive after-sales provider framework to be sure best plant efficiency and performance. Solutions contain:

Due to the fact 2010 Brickwell has helped Builders, Builders, and Architects, completely transform their dreams into gorgeous buildings that complement and enrich any setting. Brickwell is for the forefront of introducing innovating present day design products and solutions and options to enhance effectiveness and profitability.

Plant organizing and structure Manufacturing and installation Commissioning and staff coaching Uncooked material configuration and tests By specializing in read more things like manufacturing unit infrastructure, area market place developments, and environmental problems, Brickwell assures a seamless setup method that aligns with particular technological needs.

Brickwell empowers organizations by offering cutting-edge AAC plant methods that fulfill global standards, paving the way in which for a greener and more successful potential in building products creation.

This makes sure compliance with challenge specifications and facilitates efficient use in development tasks.

Jennifer Grey Then & Now!

Jennifer Grey Then & Now! Alisan Porter Then & Now!

Alisan Porter Then & Now! Michael Fishman Then & Now!

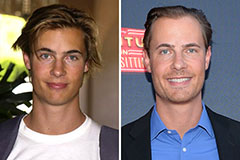

Michael Fishman Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Nicki Minaj Then & Now!

Nicki Minaj Then & Now!